How BPA’s Software Meets IATF 16949 Requirements for Automotive Industries

IATF 16949:2016 is an independent QMS standard, dedicated to the automotive sector, that is fully aligned with the requirements of ISO 9001:2015.

IATF 16949 includes specific requirements and core tools from the automotive industry, like:

- Advanced Product Quality Planning (APQP)

- Failure Mode and Effects Analysis (FMEA)

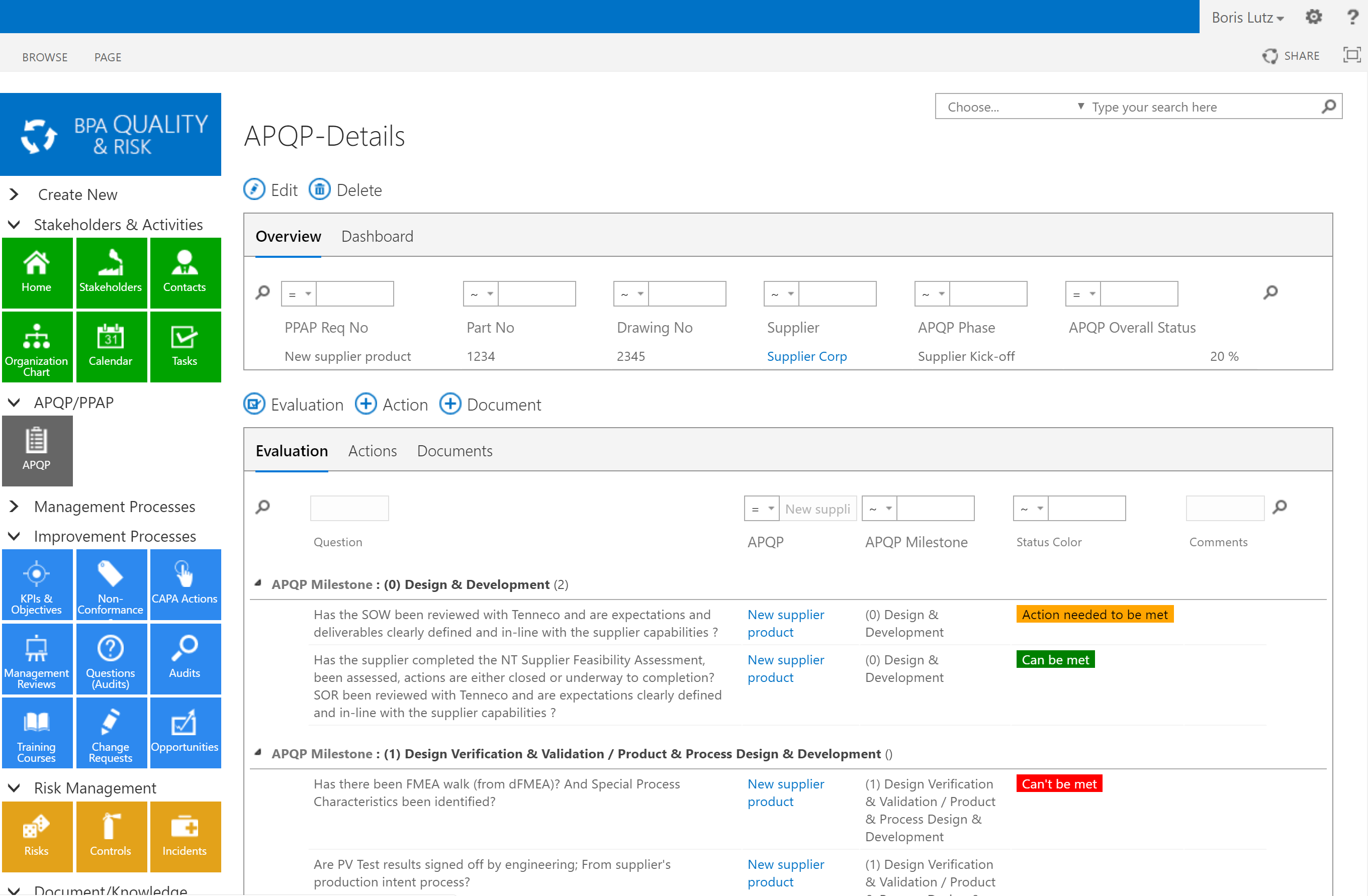

APQP ensures the voice of the customer is clearly understood, translated into requirements, technical specifications and special characteristics. APQP is typically used when introducing a new product, process or qualifying, evaluating new suppliers. From design to production, the APQP tracking sheet makes sure you go through each step and meet all needed requirements.

Screen Capture of BPA Quality & Risk Management, APQP example.

BPA’s software brings simple collaborative tools to track APQP projects with their milestones, related question sets, compliance and documents. Workflow rules ensure the right persons are automatically alerted to plan actions or mitigate risks.

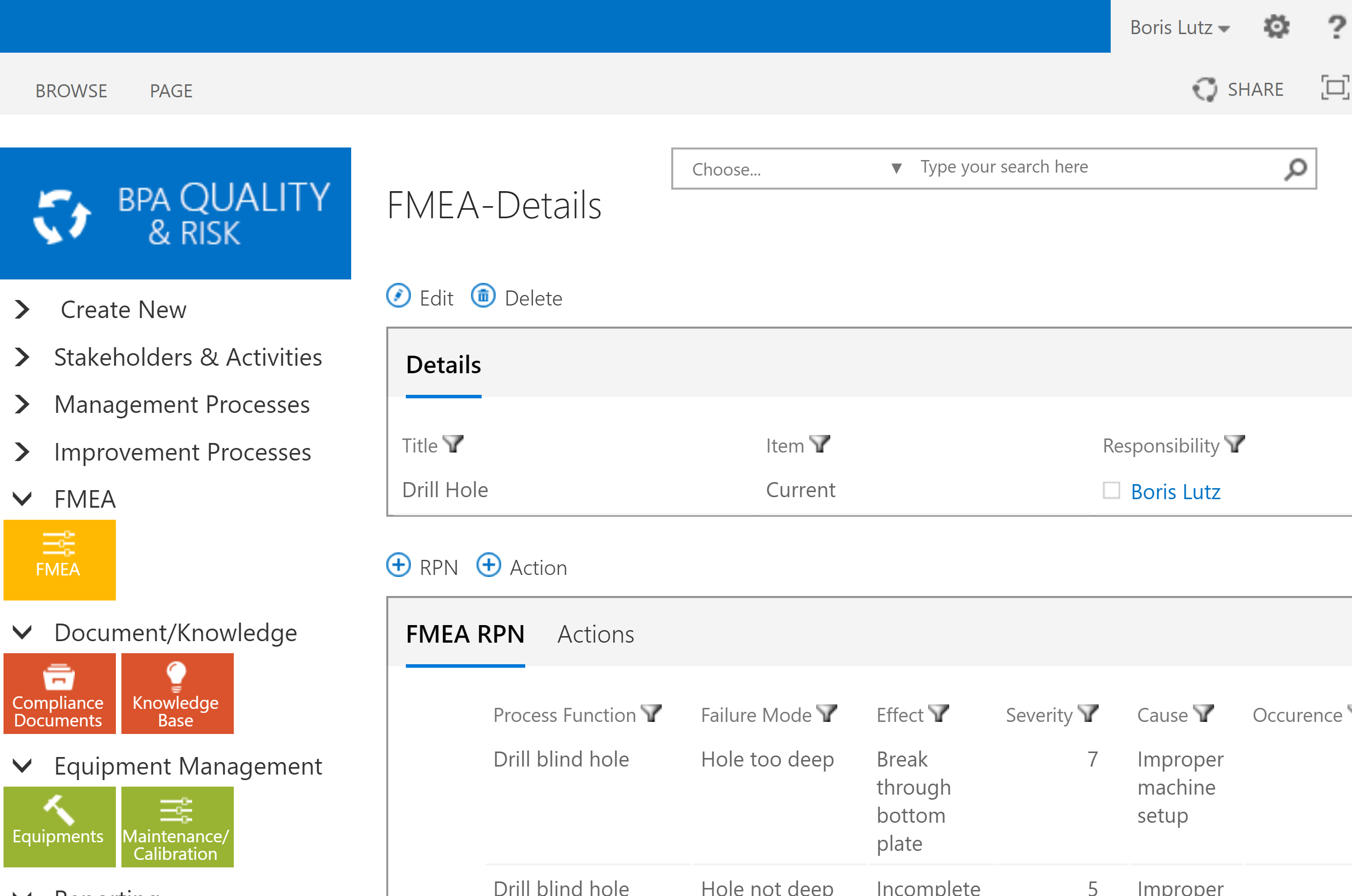

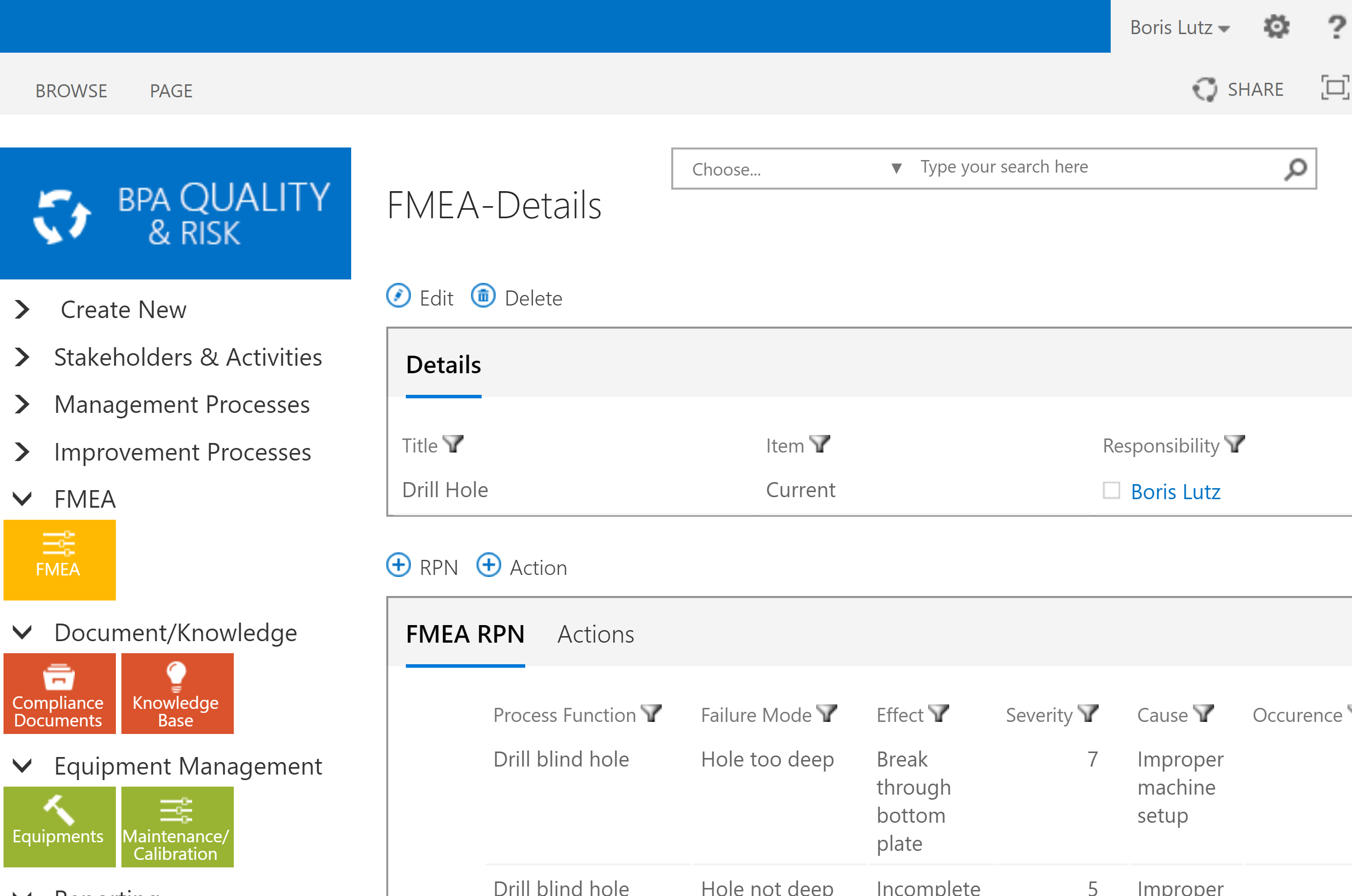

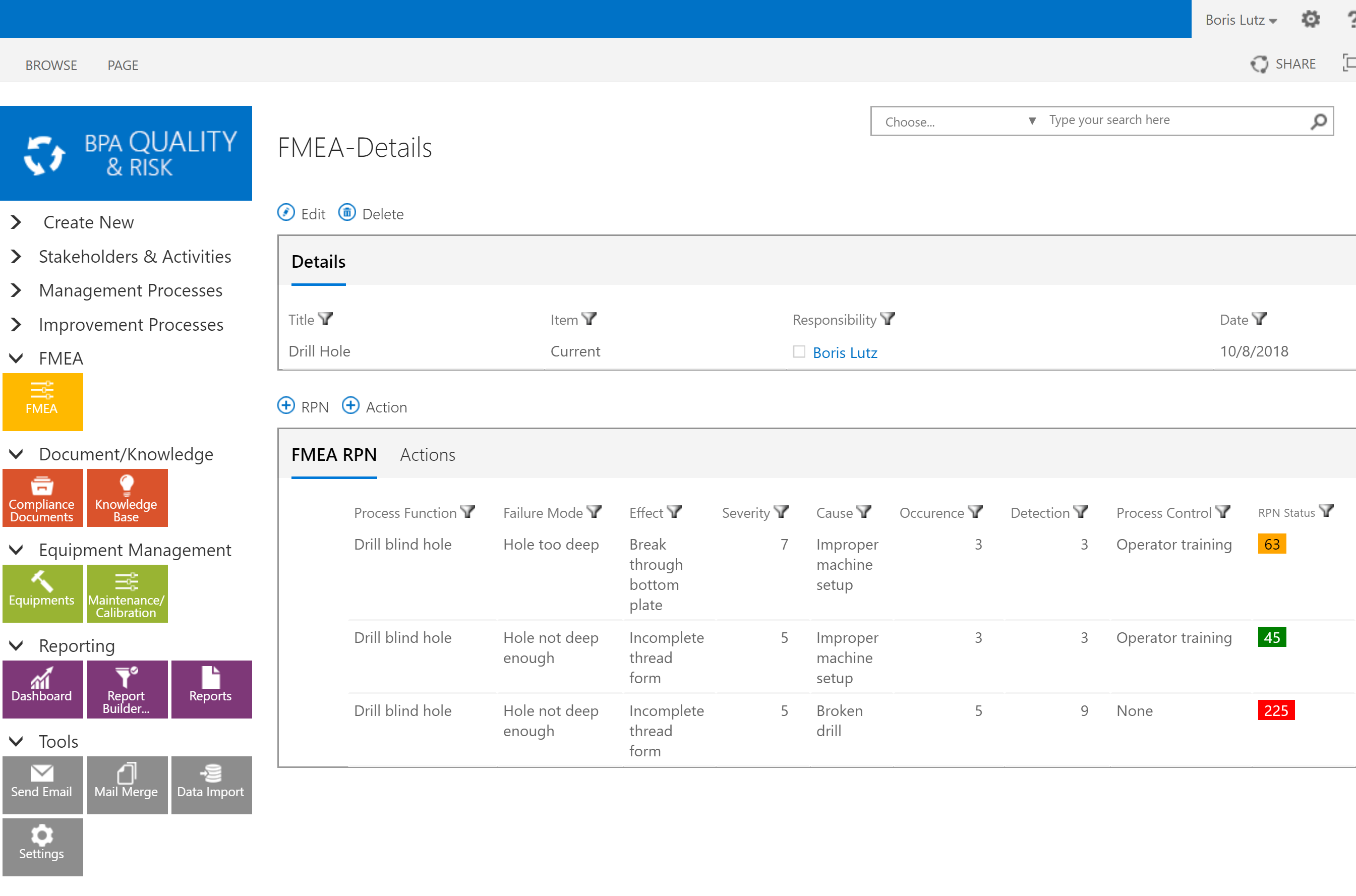

Failure Mode and Effects Analysis (FMEA) is a structured approach to discovering potential failures that may exist within the design of a product or process. Discovering a failure early in product development using FMEA improves the product design and lowers cost. Important FMEA steps are to identify failure modes and assess their severity, identify causes and probability of occurrence, set up preventive process controls (detection). As a result, FMEA highlights Risk Priority Numbers (RPN) for each identified failure mode. Actions will be taken to mitigate high risks.

Screen Capture of BPA Quality & Risk Management, FMEA example.

FMEA is a collaborative process that can be easily tracked with BPA’s software, replacing inefficient spreadsheets.

BPA Quality & Risk Management is leveraged by the benefits of Microsoft Office 365 technologies.